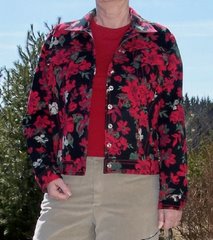

Finally back to sewing after the Christmas celebrations and busyness. Simplicity 9825, View D, went together easily right from the pattern. Size 16, no adjustments required. This was made in a bottom-weight cotton twill.

Finally back to sewing after the Christmas celebrations and busyness. Simplicity 9825, View D, went together easily right from the pattern. Size 16, no adjustments required. This was made in a bottom-weight cotton twill. I had a bit of trouble straightening the grain in the fabric, and I have to wonder if it got twisted when being washed. I had sewed the ends together and put a length of at least 3m into the wash. Perhaps that is too big a piece for an agitator-type washer. I don't remember having a problem previously with the piece I cut for my jacket lining. It was a shorter length to start with, so perhaps it did not twist. Or, maybe I was not paying attention.

I had a bit of trouble straightening the grain in the fabric, and I have to wonder if it got twisted when being washed. I had sewed the ends together and put a length of at least 3m into the wash. Perhaps that is too big a piece for an agitator-type washer. I don't remember having a problem previously with the piece I cut for my jacket lining. It was a shorter length to start with, so perhaps it did not twist. Or, maybe I was not paying attention.Anyway, after some pulling and mild cussing, the grain was in a passable state and luckily, the skirt hangs well in spite of itself.

This pattern has a wide, faced yoke at the top, and I discovered that this must be very carefully cut in order to save grief at the end. If it were necessary to make post-pattern fitting adjustments at the waist or hip, it could be quite a painful process to get facings to match the yoke exactly. The construction is similar to the plum pants waistline actually. If the side seams are taken in or let out, it would be difficult to get the exact-same seam allowances and angles on the facing. Something to fuss over, and try to get perfect on the pattern.

This pattern has a wide, faced yoke at the top, and I discovered that this must be very carefully cut in order to save grief at the end. If it were necessary to make post-pattern fitting adjustments at the waist or hip, it could be quite a painful process to get facings to match the yoke exactly. The construction is similar to the plum pants waistline actually. If the side seams are taken in or let out, it would be difficult to get the exact-same seam allowances and angles on the facing. Something to fuss over, and try to get perfect on the pattern.The skirt is eased onto the yoke, and there is a noticeable amount of ease involved. I think it is critical that the seam line be in the right place, as a even a bit narrower on the skirt side greatly increases the amount of ease to be dealt with. It could be difficult to get a smooth yoke seam in an unforgiving fabric

Twill Tape Question: The pattern suggested sewing twill tape onto the seamline when sewing the facing to the yoke. I did not do this, and it seemed to me that the twill tape would then be doubled at the edge where the facing turns back. This is edgestitched; the top of the yoke is stay-stitched; the yoke is interfaced with substantial material, so I felt the twill would be overkill. I do like the idea of something there, though, that prevents stretching at the waist. I will have to research the topic and see if the twill is supposed to be ON the seamline, or IN the seam allowance so it all turns to the back.

Research results: Julie suggests using seam binding, or a lightweight lining selvedge instead of twill on a waistline seam to reduce bulk. Now why could I not have thought of that?!

I may let the skirt hang a bit before hemming, not because it may stretch, but because I have a bit of Christmas still around my waist, and once it is gone, the skirt will drop a bit.