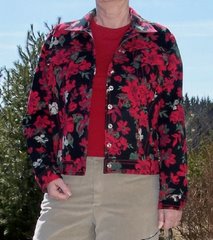

Today got off to a slow start, sewing-wise. I finally got back to the black jacquard shirt and got it cut out quite without incident. I used the pinking blade on my rotary cutter which I may turn out to regret. I started with the interfacings which put me in a muddle requiring a computer break.

The Pain of Polyester

This is a lovely fabric which I bought at Fabricville in the summer for $2.99 a meter -- so a great bargain for a test garment. I can't say that I really like jacquard -- looks like old-lady fabric to me, even though some might say I AM an old lady. I bought it shortly after I started sewing and was experimenting with various things. Also looking for bargains to experiment with.

So as I work with this, I realize what I have always known, even when I did not sew: I really don't like polyester! I find it uncomfortable to wear in hot weather and cold. For spring and fall it isn't too bad. I have a few things that are fairly comfortable most of the time; but my goodness, there must be a better way.

I try not to buy polyester fabrics, but it's like not buying pre-packaged food at the grocery store. It doesn't leave much to choose from. I have some poly in my SWAP -- the shirt stuff I bought yesterday, a green faux suede, the panne velour and a poly-viscose black which has yet to prove itself comfortable or otherwise. The rest are cottons, linens, and a wool crepe....so far.

Anyway, I will tough this one out, and the shirt ultimately will look fine. It's only a muslin anyway---and if I can make it of poly, then surely I can easily make it from whatever else is here.

Interfacing Woes

Toughing it out. Yes. Interfacing is not one of my favorite things to do. I recently gave up on fusible interfacing because it shrinks up, sometimes under the iron, and it seems like a great bother to pre-shrink, steam or whatever the rules are about interfacing pre-treatment. I think I have a mental block. Anyway, for this shirt, I decided to use a piece of fusible from my stash, cut out the facing bits and didn't have enough for the collar. Ah-ha, I said to myself. Use some of that knit fusible you have upstairs. It should be better for the collar anyway. (Why I thought it would be better is anybody's guess because interfacing is one of the gaping holes in my knowledge base.)

Carefully I cut the collar shape, then read the directions that said to trim the seam allowances to 1.8" Not to worry. Still on the ironing board which I was using for my cutting surface I trimmed the edges of the slippery slidey knit, which I discovered leaves all sorts of bits of fuzz on the black jacquard and on the ironing board cover. Without thinking much more about the fuzz, I carefully followed the rest of the application directions, using a damp cloth and appropriate pressure. I even remembered reading somewhere not to move the piece until it was cool.

While waiting, I thought I would use my iron to steam the pellon fusible pieces to be sure they would not shink later. No problem except that this is what I hate about preparing interfacing. I interfaced the back neck facing, and was about the steam the second long front facing. I picked it up and noticed the edge had gone all shrunken and squishy. Remember, I am working on my ironing board. I had taken the hot pressing cloth and placed in in the vicinity of the pellon facings. I tugged a little and managed to rip the stuff. Good grief.

Back to the drawing board. I think I'll put some sewn-in stuff in the facings, or maybe even just an extra layer of Fashion Fabric. I guess I just have to go off and study this topic, but whatever I read seems so daunting that I put it off till another day.

Meanwhile, I decided to brush the fuzz off the collar piece. Indeed! The fuzz of course, was from fusible knit -- and had nicely fused wherever the heat hit. Ah yes. Thinking IS an important part of this journey.

Still no answer from the forum on my seam-edge interfacing, but I did find out on another message board that "Fuse and Fold" is a bias fusible that has a chain stitch down the middle for stability. The writer suggested using twill tape instead, but I'm not sure that would work in this application. Maybe I can find a source of fusible bias somewhere and give it a try.

Time for supper and another tai chi class, so likely not much more progress today.

End of Day Progress

After 10:00pm is not the best time for sewing, as evidenced by the seams being picked out, but I did start the shirt, and got the interfacing finished, the edge of the front and neck facings bound, and the collar sewn together and topstitched. Only 2 short seams had to be completely removed and redone.

It's an easy pattern, and tomorrow should see most of the shirt finished -- with luck and a little time, then I will get back to the velour tank top and see what can be done there.

Subscribe to:

Post Comments (Atom)

No comments:

Post a Comment